TechAmor

For the Love of Technology

TechAmor

A Multi Technology Portal for Tech Enthusiasts

Your Company Address

India

Submarine cables are laid down by using specially modified ships (sometimes even purpose built ships) that carry the submarine cable on board and slowly lay it out on the seabed as per the charts/plans given by the cable operator. The ships can carry with them up to 2,000 kilometers length of cable.

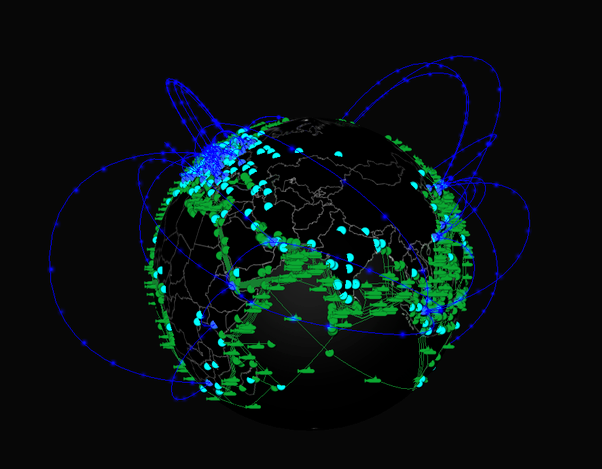

Submarine Cable Map

Depending on the equipment on-board the cable-ship, the type of plough used, the sea conditions and the ocean-bed where the cable is being laid-down, cable ships can do anywhere from 100-150km of cable laying per day. Newer ships and ploughs now do about 200 km of cable laying per day.

The ships are commonly referred to as cable-layers or cable-ships.

The cables are specially constructed for submarine operations as they have to endure harsh conditions as well as pressure.

Cable Dissection

Here is what a typical 3-D cross-sectional cut-out of a submarine cable looks like:

These fibre optic cables carry DWDM (http://en.wikipedia.org/wiki/Wavelength-division_multiplexing) laser signals ( TCP/IP packets etc. ) at a rate of terabytes per second. They use optical repeaters to strengthen the signal which attenuates over long distances. These are powered by copper cables shown above.

They have a decade lifespan and costs vary (depending on the length of the cable). Typical costs for projects are anywhere from US$ 100 Million to $500 Million.

We don’t use satellites because they can’t carry terabytes of data for less than a billion dollars per communication line.

In real-life the cable would look like this:

Here is another look…

Depending on where the cable is being laid, it might differ in thickness. Thinner cable systems are used for shallower ocean depths, whilst thicker cables are used for deep ocean beds, typically up to 20,000 feet. Such cables are able to withstand pressure from 12,000 lbs/square-inch to 22,000 lbs/square-inch (this is necessary because of the extreme pressures in the deep ocean beds.

Submarine cable laying process starts from the Landing Station, where a long cable section is attached (connected) to the landing-point and then extended out to a few miles in the sea. This end is connected to the cable on the ship and then the ship starts its cable laying process

This is how the cable approaching the landing station looks like (notice the cable laying ship in the horizon):

Depending on the geography of where the cable is laid out, the cable coming in from the ocean to the landing station might be advertised or not. Most of the time, it is buried as much as it can be and warning signs are placed so as to inform everyone that a submarine cable is landing ashore. Most of the time cable consortium companies try to hide the cable as much as they can, so that only those who need to know, are informed of the exact route of the cable. This would include municipalities, port authorities and shipping companies.

The market for submarine cables is dominated by Europe (UK, Italy, France, Germany) and a bit by Japan. US is overall a small player when compared to the others, as US itself did not have much need to expand cables to other countries, as much as the other countries had a need to connect to the US.

The ships, which are specialized, are almost all owned by the submarine cable consortium or manufacturers. These ships are stationed at various points along where the cable extends to ensure that in the event of a cable-cut, the ships can set sail immediately for cable repairs.

A cable laying ship at port

Cable coiled up in the cargo-hold (the coiling of 100s of miles of cable in the cargo hold is a process that can take between 3 to 4 weeks to complete.

Another picture of Fiber Optic Cable being carefully wound and rolled into the cargo hold.

Another submarine cable laying ship at port

Cable Landing Install Ship (that connects the Landing Cable to the Ocean Cable)

The portion of the ship from where the cables are lowered into the sea

Cable turntable – the turntable is slowly unwinding the cable and lowering it on to the ocean floor.

A cable laying ship at sea. Notice the cable being lowered onto the sea bed, on the right-hand (starboard) side (white portion) at the rear end of the ship.

Here is a photograph of a repeater being launched into the sea (which is placed every 40-60 kilometers) to fix and strengthen the fiber-optic signal and to amplify it, etc. These are powered by the copper cables which are wrapped around the fiber optic cable as shown below.

The process also involves a plough. The cable is not simply left to just sit on the ocean bed, but is actually being fed into a plough, that is laying the cable in the trench.

Here is the process as seen of submarine cable laying (with the plough)

Here is another perspective of the same (you can see how the cable is being fed into the trench)

Here is the cable-plough on shore, being slowly pulled to the ocean

Some of these ploughs are hydraulically assisted and most use water jets to easy trench clearing.

Here is another smaller cable plough

A submarine cable diver, inspecting a submarine cable.

When cables are damaged, either divers or specialized small submersibles with cameras and lights are sent down to the seabed to investigate where the cuts are. Then, either the divers or robotic arms on the submersible bring the two ends of the cable to the surface, where they are re-spliced and joined again.

Here is an example of a submarine cable robot, that is lowered onto the sea bed to retrieve each end of the broken / damaged / sliced cable and send it to the surface ship for repairs

Different cable types (by Alcatel)

Work on Submarine Cable Between Malta & Sicily Underway

NKT Cables Opens Logistics Center in the Port of Rotterdam (Netherlands)

Dhiraagu (The Telecom company for Maldives) laying submarine cable across Maldives

Submarine Cable ship, with the Cable turntable nearly empty

This is a great site that shows a 3-D Map of all the submarine cables: HE 3D Network Map

Fascinating , isn’t it !!

Subscribe to our page for more Updates.